aicas Use Cases

Learn how customers successfully implemented aicas IoT and automotive solutions

aicas’ products are used in millions of devices and vehicles. Various industrial companies, car manufacturers and their suppliers are successfully using aicas for their embedded IoT and cloud-to-edge solutions. 5 of the 10 biggest automotive manufacturers rely on aicas.

Sign up for the aicas newsletter to be informed about new whitepapers and use cases.

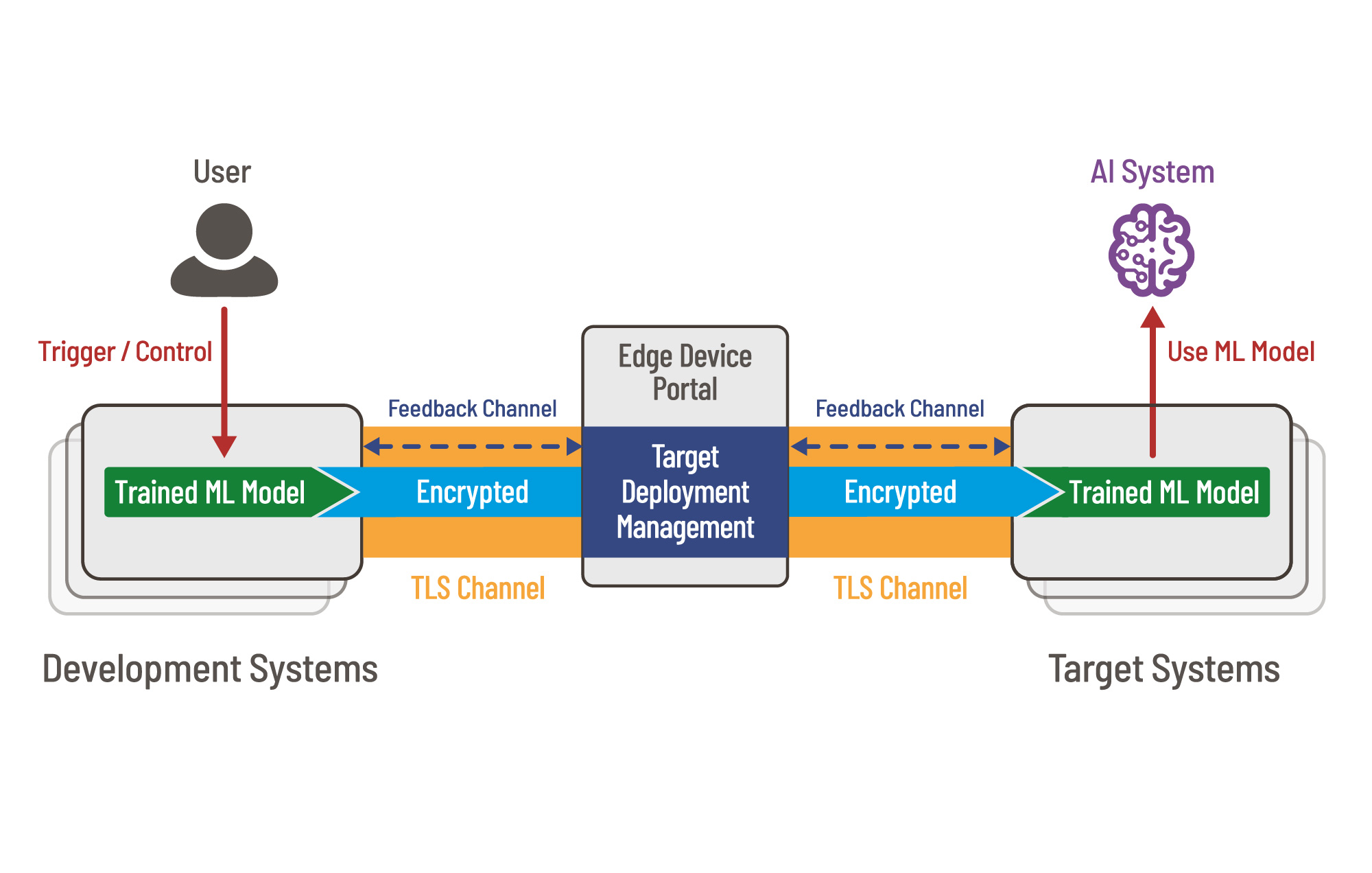

Secure ML Model Distribution for AI Edge Systems

WHO

Industrial Automation AI System

WHAT

AI models need to constantly learn and improve. Updated models must be reliably and securely transferred to the target system at the edge and protected from unauthorized access.

HOW

aicas’ cloud-based Edge Device Portal (EDP) for streamlining software updates to edge devices enables secure and robust ML model updates. With a single click, ML model updates can be distributed (upload, download, install, start, stop) to remote AI systems at the edge – all without accessing or modifying the models themselves. The solution provides encrypted, signed components and TLS-protected channels.

VALUE

The solution ensures the secure and robust deployment of ML model updates.

Intelligent Automation and Data Security in Smart Warehouses

WHO

KUNBUS GmbH

WHAT

This use case showcases an integrated solution for smart warehousing, addressing data integrity, and cybersecurity challenges.

HOW

Developed collaboratively by KUNBUS, Swissbit, AWS, Klika Tech, and aicas, the solution utilizes smart shelving, AWS IoT Services, and hardware security modules for centralized data management and realtime visibility.

VALUE

By combining automation and robust security measures, the solution optimizes efficiency, enhances security, and facilitates rapid development, leading to significant cost savings and revolutionizing logistics operations.

Vehicle Data for Insurance Risk Management

WHO

A provider of vehicle Data

WHAT

Streamlined process for providing vehicle data to external data consumers such as insurers.

HOW

Data consumers can easily request specific vehicle data parameters from OEMs or data brokers through a user-friendly interface.

VALUE

Simplified time-saving data monetization process, enhanced revenue generation, and strengthened partnerships between data providers and consumers such as insurance companies.

Data-driven Insights in DevOps

WHO

Automotive OEM

WHAT

Data monitoring within the virtual DevOp environment for software-defined vehicles.

HOW

Easily select, pre-process, and visualize edge data streams in a dashboard in a cloud.

VALUE

Valuable insights enable informed decisions and rapid response, resulting in significant operational and cost savings, as well as improved vehicle safety and performance.

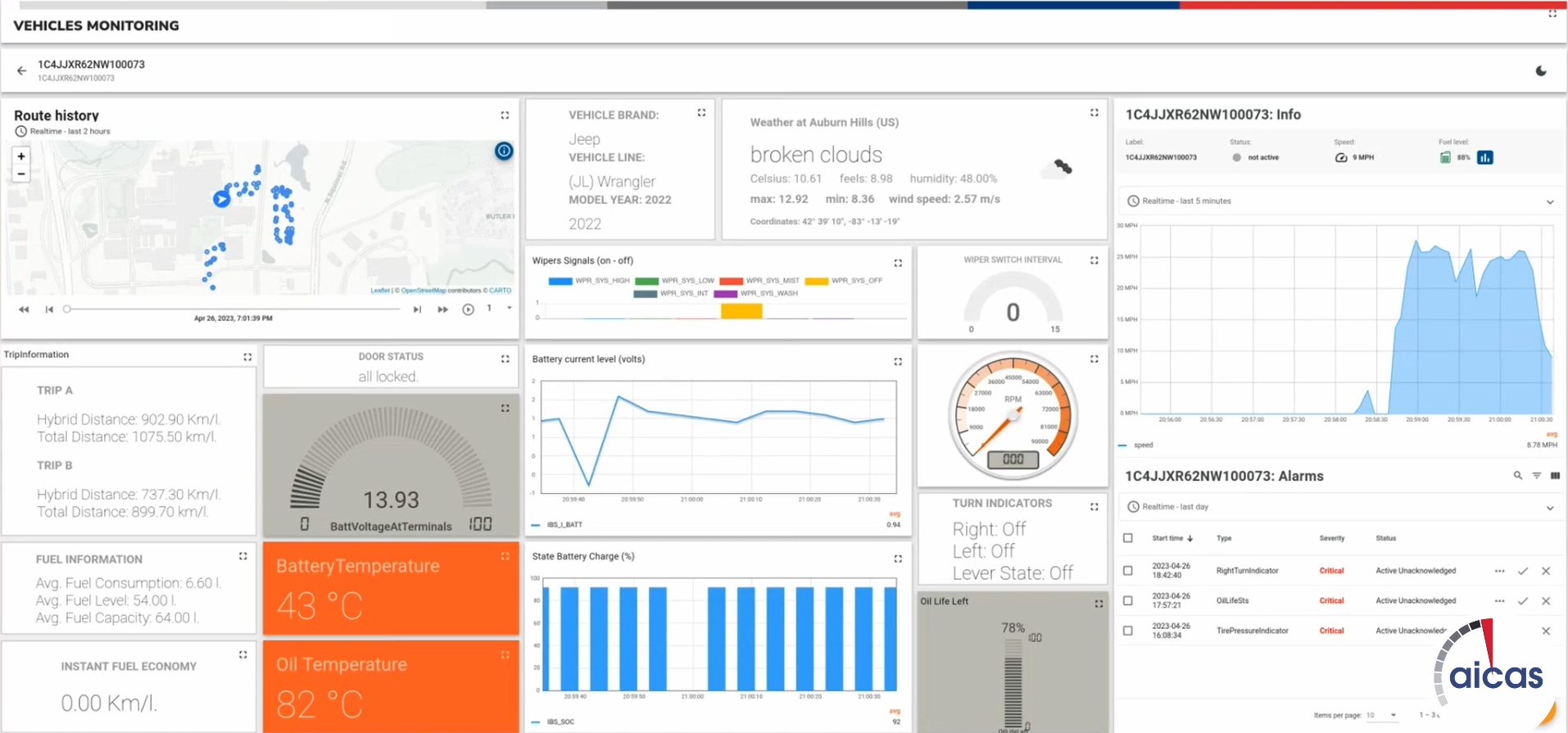

Live Data Management

WHO

Leading Automotive Original Equipment Manufacturer

WHAT

Integrate, select, and visualize live vehicle data in a dashboard to gain insights in realtime.

HOW

The aicas solution provides seamless access to realtime vehicle system data, such as vehicle diagnostics, sensor readings, and GPS locations. The dashboard analyzes, extracts, and visualizes insights from incoming live data streams. This enables live monitoring of speed, position, battery status, vehicle fault indications, fuel consumption, distance traveled, and much more. The solution provides over 100 configurable graphical widgets and can be used without programming skills.

VALUE

The insights provided by the dashboard enable operational and cost efficiencies as well as improved safety and performance. Decisions, responses, and actions can be taken immediately and cost effectively.

USE CASE DEMO

At the Covesa All Member Meeting 2023, aicas unveiled its Live Vehicle Data Dashboard for the first time.

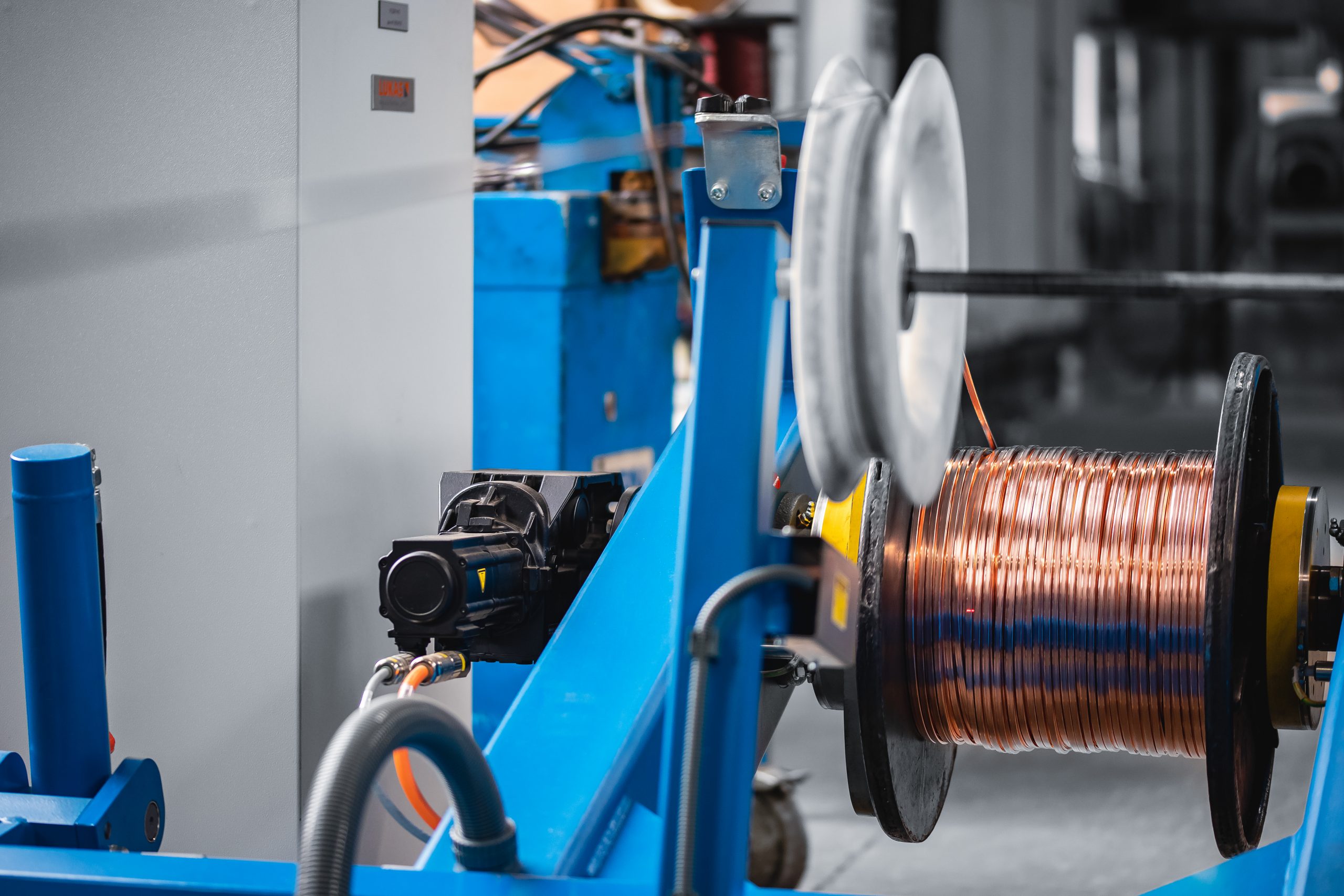

Realtime Operation

WHO

High-tech wire processing machine manufacturer

WHAT

The production processes require a reaction time of less than 1ms. The software developers needed a safe and simple programming interface for the tools they are developing.

HOW

By using aicas’ JamaicaVM, a deterministic and realtime embedded virtual machine, Java programming is simplified. At the same time, it ensures very short execution times, such as the 1 ms required by the company’s production equipment.

VALUE

These machines are renowned for their robustness and unparalleled quality. JamaicaVM extends these quality capabilities while bringing simplicity of use on top of companies’ quality standards.

Embedded Sandboxing

WHO

Healthcare, manufacturer of ventilators

WHAT

Use artificial intelligence to monitor the functions of the machines.

HOW

Patients’ lives depend on ventilators. Therefore, the software running the basic operations of the system needs to be shielded from the artificial intelligence used to monitor the ventilator’s functions. The customer, a large German manufacturer of medical technology, uses the virtualization capabilities of aicas’ Jamaica VM to seperate core functionalities from the AI.

VALUE

It ensures the ventilator’s basic software remains operable, even if the AI wants to use more system resources than it should. The Jamaica product family prevents memory or CPU usage beyond defined limits, thus protecting key application functions.

Realtime Operation

WHO

Company in textile testing and quality control

WHAT

The company’s goal was to provide an intuitive, smart touch controlled user interface for its yarn quality control system. The challenge was to develop a programmable graphical user interface that runs with an ontop realtime operating system on a microprocessor with constrained resources.

HOW

aicas’ JamaicaVM fits critical operations in uninterrupted processes with standards-based graphical capabilities.

VALUE

The company’s customers enjoy efficient user interfaces, while software developers benefit from standard programming tools for their applications, without compromising realtime response.

Application Management

WHO

Various Automotive OEMs

WHAT

Helping car owners and the police to return your car after theft.

HOW

aicas enables the upload of software to vehicles. In case of theft, the application can – if properly authorized – provide vehicle data to the authorities. The vehicle’s location can be traced at any time, certain vehicle functions can be turned on and off. Even interaction with the driver is possible. If the vehicle stops, e.g., at a red light, the onward journey can be prevented.

VALUE

The solution allows for a quick and easy upgrade to the desired software version for all processes and functions. Lifecycle management can be expanded to the functions of underlying, connected microprocessors. Completely remote and just with a few buttons, single devices, any selection of devices – even according to specific requirements, such as location, language, etc. – up to millions of devices can be managed – quick and simple.

Smart Cities

WHO

Public Services

WHAT

When time is of the essence, technology should not be an issue. First response services, such as police and fire departments, shouldn’t be delayed by slow technology or services that are not available.

HOW

With aicas EdgeSuite running on AWS Wavelength, public services can rely on ultra-low latency services. This solution allows to run the needed services directly where they are needed, and not in some data center on the other side of the globe.

VALUE

Imagine a building is on fire. The first responder doesn’t know where the people are, but they need to go there NOW. With a people detection system that comes on when the emergency lights turn on, the people in a building can be located via triangulation. Saving lives, as it is easy to find out where people are. Informing the first responders on smart devices where they need to go to. Coordination with others – even without power in the buillding – becomes reality.

Platform Porting

WHO

Semiconductor Manufacturer

WHAT

Computing platforms become of age. Switching from one system to the next is not always straightforward or easy, and resources are always tight.

HOW

With JamaicaVM, this customer was up and running on the new platform in no time. With its broad support of hardware platforms by a wide range of manufacturers and many supported operating systems, the Jamaica product family is the first choice for porting systems to new platforms.

VALUE

This allows for a faster upgrading process without the need to rewrite code, significantly decreasing the costs of modernization.

Telematics

WHO

Various Automotive OEMs

WHAT

Using telematics data generated from automotive sensors to improve driving safety and create innovative services.

HOW

aicas’ telematics product provides features for the era of connected vehicles. It enables vehicles to connect to the road infrastructure and other vehicles by using onboard wireless communication technologies. The connected vehicles provide shared services and exchange vehicle information with each other to respond to the traffic situation.

VALUE

In the attached document, we provide details on many different telematics use case scenarios based on aicas’ telematics capabilities, TCU architecture, required functions of telematics systems, intra-vehicle network, V2X interface, diagnostic interface, bus implementation, data security, over-the-air (OTA) vehicle updates, logging and tracing, and reference applications.

Over-The-Air Updates

WHO

IIC, AASA, aicas

WHAT

An Automotive Over-The-Air (AOTA) Updates Testbed that demonstrates how software can be remotely managed on a fleet of vehicles.

HOW

The base architecture is built around a Telematics Unit (TU) managing the connection to the external network. The TU has connections to the internal busses: ethernet and CAN. On the TU, a realtime OSGi framework with resource enforcement is used to manage the software lifecycle. By running an instance on each domain controller, customers can track the software on each instance. An additional level of segregation is achieved by running system and external software in a container, running as a separate process, in an FPGA, on a GPU, or on a microcontroller.

VALUE

Connecting a vehicle to the internet is just the beginning of digital transformation. This testbed demonstrates how connectivity can be used for effective data collection and remote software maintenance. Keeping the cloud-to-vehicle connection secure is essential for this transformation.

Abstraction

WHO

AWS Amazon Web Services

WHAT

Downsize and bring AWS IoT Greengrass 2.0 where no one has ever brought it before.

HOW

AWS, the world’s largest cloud provider, uses JamaicaVM as a runtime for their AWS IoT Greengrass 2.0 product. aicas ported JamaicaVM onto a RISC-V based hardware running a Linux operating system within less than a day. Once JamaicaVM was running on this RISC-V board, aicas engineering then ported AWS Greengrass 2.0 to this JamaicaVM enabled computing platform.

VALUE

Support of new and additional computing platforms is a must for any embedded system. Providing the abstraction as well as the broad range of operating systems and hardware platforms via JamaicaVM means that AWS customers can focus on what is really important: capturing value from their IoT systems without having to worry about the underlying infrastructure, even when new computing platforms have to be introduced. Reuseability of the systems is a given.

Intelligent Data Management

WHO

Aircraft Manufacturer

WHAT

Provide a solution that enables long-haul aircraft to transmit relevant data to the ground crew immediately after landing.

HOW

JamaicaVM is able to collect and automatically send the correct data, meaning the actually relevant data, when needed. All this can be done in realtime while maintaining the most stringent safety requirements. With that, JamaicaVM is the basis for data automation solutions.

VALUE

The data does not have to be pulled manually, and data transmission can be done after touchdown with significantly less cost per MB than with a satellite connection. Potential technical issues can be identified immediately, the ground crew can react even before the plane has reached the docking port. Turnaround or downtime of the plane is kept to a minimum, resulting in a competitive advantage.

Logic Management

WHO

Siemens Industrial Automation

WHAT

Siemens high-end motion control system “Simotion”: provide customers with robust means to program devices, while maintaining a clock cycle below 125µs.

HOW

aicas’ embedded JamaicaVM runs Java code with standards based hard realtime capabilities. This is based on aicas’ deterministic garbage collector.

VALUE

JamaicaVM enables robust device programming, thus reducing the cost of customization for both Siemens and its customers. JamaicaVM has been in operation on Siemens Simatic for over 10 years.

Application Management

WHO

3 of the 5 leading automobile manufacturers

WHAT

Provide in-vehicle infotainment (IVI) and telematics platform supporting over-the-air updates.

HOW

Use aicas EdgeSuite runtime JamaicaCAR for app development and deployment, thus providing a secure, robust, and consistent framework for running and updating IVI apps over the air. The framework runs on QNX, VxWorks, as well as a broad range of other RTOSes.

VALUE

A consistent programming interface (IVI platform) covering multiple vehicle generations and three tier-one suppliers for running and dynamically updating deployed infotainment and telematics systems. JamaicaCAR provides the same capabilities as Android, but requires less computing power and memory while preserving the OEM’s control over the user experience and data.

Intelligent Data Management

WHO

Claas (Harvesters / Agriculture)

WHAT

Bring new information to the driver of the harvester to maximize yield by improving harvester operation, machine efficiency and utilization.

HOW

aicas’ JamaicaVM is used to process machine data from the harvester’s CANbus.

VALUE

Machine throughput was increased. The harvester operator experiences higher comfort and more efficiency. Claas has been able to win market shares thanks to these new features.

Sensor Connectivity

WHO

Legacy factory

WHAT

Making a legacy factory smart: Implementing IoT systems for manufacturing is almost never a greenfield approach. It is always about retrofitting existing factories or machinery.

HOW

aicas EdgeSuite connects sensors via an Espressif ESP32 to connect IO-Link to the cloud with WiFi and MQTT.

VALUE

An inexpensive, scalable, decentralized, plug-and-play solution that can be maintained with OTA updates. The installation of sensors is easy and fast without interrupting the production cycle and without the requirement of software development or difficult configurations on-site.

Abstraction

WHO

Automotive Original Equipment Manufacturer

WHAT

Application management – Reduce the software complexity for different automotive brands, vehicle models, platforms, and subsystems.

HOW

The automotive EdgeRuntimes of aicas EdgeSuite for automotive provide an abstraction for all the ECUs in a car from the underlying computing platform. Moreover, these EdgeRuntimes support a broad range of embedded technologies and (automotive) protocols. This enables software reuse across models and brands.

VALUE

aicas EdgeSuite enables the complete lifecycle management of different ECUs and connected subsystems in one comprehensive system.